VIP member

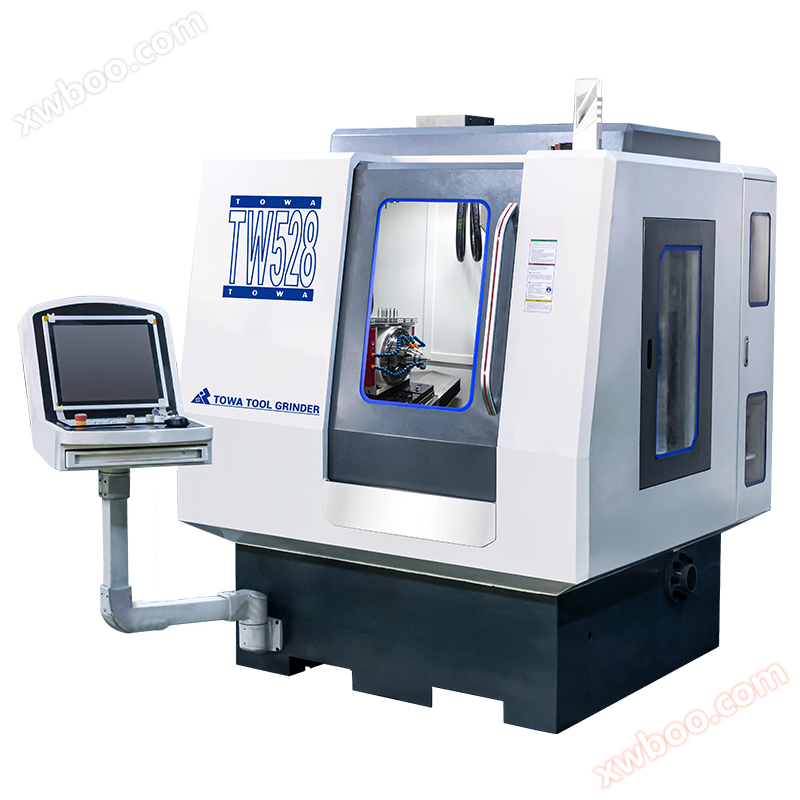

TW528 Five Axis CNC Tool Grinding Machine

1、 Introduction to Machine Tool TW528 is a newly developed five axis five linkage CNC tool grinder by our company. It is a cost-effective tool grinder

Product details

content·Detailed

1、 Introduction to Machine Tool

TW528 is a newly developed five axis five linkage CNC tool grinder by our company. It is a cost-effective tool grinder suitable for production orGrinding various milling tools, drilling tools, forming tools, etc.

1. The machine tool has a simple design, friendly human-machine interface, natural marble components, and good stability.

2. The machine tool adopts a high-precision, synchronous direct drive variable frequency electric spindle, which has two sets of grinding wheel flanges. Each set of flanges can accommodate 2-4 grinding wheels at the same timeGrinding process, quick rotation of grinding wheel group, can fully meet various tool grinding needs.

3. The workpiece spindle adopts DD direct drive, Schopenberg chuck body and cylinder clamp, and the workpiece is automatically clamped.

4The machine tool adopts the new generation 210MA-5E five axis linkage control system and servo unit, and uses Pioneer precision measuring head, upper silver precision rolling line track andBall screw ensures superior performance and working accuracy of the machine tool.

5The machine tool adopts a fully enclosed appearance (front movable sliding door, maintenance doors on both sides), swing arm control panel, handheld electronic handwheel, and dedicatedStart stop button, configuration of automatic oil cooler and workpiece cooling control device, configuration of automatic lubrication device and mist suction interface, alarm buzzer, configuration of electricThe cooling air conditioner in the machine box makes the operation, maintenance, and changes of the machine tool simple and convenient.

2、 Technical parameters

2、 Technical parameters

| Numerical Control System | New generation 210MA-5E | Clamping range of clamp for workpiece | 3~20mm |

| Grinding software | TW tool grinding software | Maximum rotation speed of grinding head swing (C-axis) 30 | rpm |

| Maximum diameter of processed workpiece | 200 mm | C-axis rotation range | 325°(+230°~ -95°) |

| Maximum workpiece length for grinding | 170mm | Workpiece spindle center height | 150mm |

| Maximum groove depth for processed workpieces | 10mm | Radial runout of workpiece spindle | ≤0.005mm |

| maximum workpiece weight | 10Kg | Radial runout of grinding head spindle | ≤0.005mm |

| Maximum power of grinding head (direct drive electric spindle) | 11KW | Cylinder thrust range | 500-580kg |

| Grinding wheel size (CBN/diamond) | Φ50~Φ200mm | Linear axis resolution | 0.001mm |

| Grinding head spindle speed (variable frequency speed regulation) | 1000-8000rpm | Rotation axis resolution | 0.001° |

| Vertical lifting stroke of grinding head (Z-axis) | 320(-100~220)mm | power supply | AC 380V 50HZ three-phase |

| Workbench travel X-axis/Y-axis | X:460 / Y:400 | Total power of machine tool | ≤26KW |

| Rapid movement speed of linear axis | 15m/min | overall dimension | 1700x1520x2100mm |

| Workpiece spindle speed (A-axis) 5 | 00rpm | Machine weight | 3T |

| A-axis rotation range | 360° | ||

| Automatic clamping of workpiece range | 3~20mm |

3、 Standard configuration

Machine host, new generation 210MA-5E CNC system and servo unit, tool software package, Pioneer probe, 11KW precision direct drive grinding head, HSK quick change precision flange rod, W25 workpiece automatic clamping device, mist suction interface, automatic lubrication device, automatic cooling control device.

4、 Optional configuration

Kobelin W20 handle and clamp, specialized fixture, grinding wheel, automatic feeding device, Renishaw LP2DD probe from the UK, Marposs probe from Italy, etc.

Online inquiry