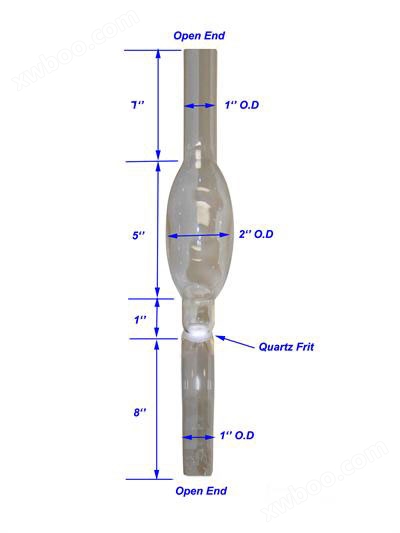

OTF-1200X-S-FB is a fluidized bed vertical tube furnace specifically designed for CVD experiments on powder surface deposition. The furnace tube is made of high-purity quartz and is embedded with a porous quartz plate with a pore size of 5-15um The powder can be placed on a porous quartz plate, and gas can be introduced from the lower end of the furnace tube to suspend the sample particles in the heating area through the porous quartz plate for deposition experiments.

| Technical Parameter | |

|---|---|

| shell structure |

● Reacting gas and uniformly passing through the reaction zone Solid particles are suspended in the heating zone by the gas introduced The furnace body is designed as an open type. After the experiment is completed, the furnace body can be opened and the quartz tube can be taken out to remove the particles after the reaction. ●Attention: When suspending sample particles with gas, the particles may pass through the heating zone due to excessive gas flow rate. Therefore, the gas flow rate should be adjusted according to the size of the particles during the experiment |

| Porous quartz plate |

Aperture: 5-15 μ m ● Size: 44mm I. D x 4mm t ● |

| Furnace structure |

Double layered shell structure with air cooling system The furnace body is designed as an open type for easy layout and sampling Using high-purity alumina fiber as the furnace material and coated with a 1760 degree high-temperature alumina coating imported from the United States on the surface can extend the service life of the instrument and improve heating efficiency |

| maximum power |

1.2KW |

| Input power supply |

AC220V single-phase, 50/60 Hz |

| Maximum operating temperature |

1200℃ |

| Continuous operating temperature |

1100℃ |

| maximum rate |

<= 20 oC /min |

| Furnace tube size and material |

Using high-purity quartz furnace tubes Furnace tube size: 50mm; ID: 44mm; L: 610mm ● |

| heating zone |

200mm (single temperature zone) |

| Constant temperature zone |

100mm(+/-2oC)Note: Due to the influence of measurement methods and external environment, the measurement results may have deviations. This parameter is for reference only and should not be used as a technical indicator of the equipment. You need accurate constant temperature zone data to purchase the product. Please contact our sales personnel |

| temperature control |

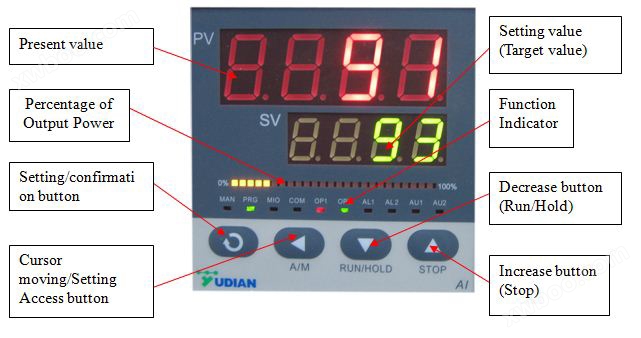

Can set up 30 temperature rise, insulation, and cooling programs. Adopting PID method to regulate temperature, with overheat and trip protection Temperature control accuracy:+/- 1 ºC ● Temperature control instrument operation video

|

| heating element |

Molybdenum doped iron chromium aluminum alloy |

| FLANGE |

The instrument is equipped with a pair of stainless steel sealing flanges, on which stainless steel globe valves and mechanical pressure gauges are installed |

| Operation video | |

| External dimensions |

340mm×300mm×1000mm ( W x L x H) |

| weight |

About 20kg |

| Warranty period |

One year warranty period (excluding furnace tubes, sealing rings, and heating elements) |

| Certificate |

● CE certification All electrical components (>24V) are certified by UL/MET/CSA If the customer incurs certification fees, our company guarantees that a single device will pass the German TUV certification or CAS certification |

| national patent |

Patent Name: A Wide Range Operating Temperature Openable High Temperature Tube Furnace Patent Number: ZL-2011-2-0389859. 8 Respect innovation, disdain plagiarism, and hold infringement accountable |

| Application precautions |

The air pressure inside the furnace tube cannot exceed 0.02MPa Due to the high internal pressure of the gas cylinder, a pressure reducing valve must be installed on the cylinder when introducing gas into the furnace tube. It is recommended to purchase a pressure reducing valve from our company, which has a range of 0.01MPa-0.1MPa and can be used more accurately and safely When the temperature of the furnace body is higher than 1000 ℃, the furnace tube cannot be in a vacuum state. The pressure inside the furnace tube should be equivalent to atmospheric pressure and maintained at atmospheric pressure The gas flow rate entering the furnace tube should be less than 200SCCM to avoid the impact of cold large airflow on the heated quartz tube The long-term use temperature of quartz tube is less than 1100 ℃ It is not recommended to close the exhaust and intake valves at the flange end of the furnace tube for sample heating experiments. If it is necessary to close the gas valve to heat the sample, it is necessary to constantly pay attention to the reading on the pressure gauge. If the pressure reading is greater than 0.02 MPa, the vent valve must be opened immediately to prevent accidents (such as furnace tube rupture, flange flying out, etc.) |