|

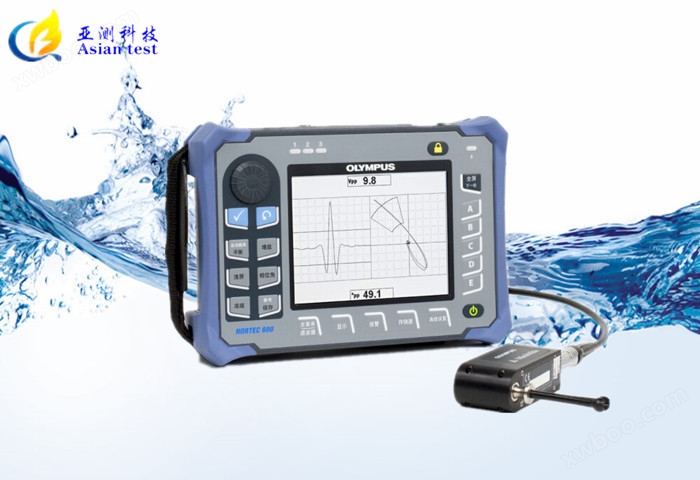

NORTEC 600 eddy current flaw detector

|

|

☆ Measurement range: 1mm to 10160mm

|

|

☆ Operating frequency: 635 m/s to 15240 m/s

|

|

☆ Detection accuracy: 0.2 MHz to 26.5 MHz

|

|

☆ Indication error: 0.01mm

|

Product Introduction

----------------------------------------------------------------------

overview

Olympus has integrated the most advanced technologies in high-performance digital circuits and eddy current testing into this compact, portable, and durable new NORTEC 600 instrument. The NORTEC 600 comes with a clear and bright 5.7-inch VGA display, and features a true full screen mode that can present highly visible and contrasting eddy current signals in any lighting condition.

The redesigned interface of NORTEC 600 borrows the intuitive, knob operated browsing method of the previous generation NORTEC products, and combines this method with the simple menu structure and efficient shortcut keys used by other popular Olympus instruments. The NORTEC 600 has four versatile models with a plethora of innovative features, including an application selection menu, all-in-one display, real-time reading, and signal calibration in freeze mode, ensuring that any level of operator can quickly and easily complete the inspection.

Reliable performance, sturdy and durable

The casing of the NORTEC 600 instrument has been field verified to be very sturdy and durable, and can operate normally in harsh field environments. Due to the durability of the NORTEC 600 casing against extreme weather conditions, it can ensure that users can smoothly complete any eddy current testing work.

Portable and lightweight

The NORTEC 600 weighs only 1.6 kilograms and is equipped with a wrist strap installed by the manufacturer. The wrist strap helps operators directly use their thumb to control buttons, providing them with the true multifunctional features of handheld instruments.

Main characteristics

- Designed to meet IP66 requirements

- Compliant with EN-15548 standard

- Long term battery operation time (up to 10 hours)

- 5.7-inch bright VGA display screen

- Full screen options in all display modes

- Improved filter for rotating scanner mode

- Intuitive interface with pre-set application options

- All settings configuration pages

- Wide frequency range from 10 Hz to 12 MHz

- Automatic internal balancing (BNC interface)

- There are at most two real-time readings

- True automatic mixing function

- Storage capacity up to 500 files (programs and data)

- Airborne file preview

Versatility and compatibility

4 models to meet all user needs

NORTEC 600 has four widely used instrument models that can meet various testing needs of users. Starting from the basic model, each model of instrument unlocks more available features than the previous one. To provide greater convenience to users, we can also remotely unlock more other features for them.

| Supported functions or modes | N600 (Basic) | N600C (conductivity) | N600S (scanner) | N600D (dual band) |

| Signal calibration in freeze mode | √ | √ | √ | √ |

| Real time reading | √ | √ | √ | √ |

| Application selection | √ | √ | √ | √ |

| Multi in one display | √ | √ | √ | √ |

| PowerLink probe support | √ | √ | √ | √ |

| Measurement of conductivity and coating thickness | √* | √ | √ | |

| Rotating scanner | √ | √ | ||

| Dual frequency and hybrid | √ | |||

| *Includes 1 conductivity probe 9222340 [U8690027], standard test block 9522103 [U8880111], and calibration pad 0320806 [U8840160]. | ||||

Two probe interfaces

All models of NORTEC 600 are equipped with a standard LEMO 16 pin universal interface and a BNC interface for absolute probes. Users only need to select the appropriate interface in the instrument interface. When connected to the BNC interface, the instrument has an automatic internal balancing function, eliminating the need for manual balancing operations.

The 16 pin LEMO interface also supports PowerLink NORTEC technology, which can perform automatic probe recognition and has instrument preset function for faster instrument settings.

Compatible with current testing programs and testing programs from other manufacturers.

To simplify detection operations, NORTEC 600 includes all traditional modes and layouts used in existing NORTEC specific detection programs, as well as those used by many other device manufacturers. The standard impedance diagram view, sweep mode (strip chart), split screen display, adjustable balance point, crosshair, improved filter response, reference signal display, and many other useful features are included in the NORTEC 600 package.

The accessories of NORTEC 600 include various cables and adapters, such as 12 pin LEMO, 11 pin Fischer, etc., making it compatible with many other probe and rotary scanner manufacturers' products. Appropriate adapters or scanner cables can enable operators to utilize all the excellent performance of the NORTEC 600 instrument using only existing probes, without having to spend a lot of money on purchasing other probes and accessories.

Presenting the Brightest Display Images in the Industrial Sector

Bright VGA display

The NORTEC 600 is one of the brightest display images in the portable eddy current flaw detector market. Thanks to the unique brightness, resolution, and clarity of its 5.7-inch VGA display, users can read eddy current signals on the screen from a distance. Users can choose color screen settings, so whether using NORTEC 600 indoors or outdoors, the images on the screen will be equally clear and easy to read.

True full screen display

The impressive VGA display of NORTEC 600 is not only spacious and bright, but also adds a full screen mode. Users only need to touch the button to activate this full screen mode.

Full screen mode exists in all applications and display modes, and when reading signals during extended periods, this feature truly facilitates user operations.

Based on the NORTEC 600 model instrument owned, users can choose the following displays:

- Single impedance diagram

- Double impedance diagram

- Sweep frequency chart (strip chart)

- Split screen display (sweep frequency+impedance)

- waterfall

- Multi in one display, capable of displaying up to 3 configurable trajectories

The integration process between NORTEC 600 and the detection system is very simple

The NORTEC 600 instrument can be seamlessly integrated with any integrated eddy current testing system. The NORTEC 600 instrument has many software and hardware features that ensure consistent flaw detection operations with the entire detection system in industrial environments. The design of NORTEC 600's technical specifications and functions takes into account the existence of integration circuits.

- Designed to meet IP66 requirements

- -Operating temperature range from 10 ° C to 50 ° C

- Continuous balanced filter

- Belt chart view with sweep frequency alarm

- Measurement rate of 6 kHz

- Remote control from NORTEC PC

- ALARM IN

- Analog Output

- Digital input

technical specifications

| casing | |

| External dimensions (Width x Height x Thickness) |

236 mm × 167 mm × 70 mm |

| weight | 1.7 kilograms, including lithium-ion battery. |

| Standard or instruction | EN-15548, CE, WEEE, FCC (USA), IC (Canada), RoHS (China), RCM (Australia and New Zealand). |

| Power requirements | AC main power supply: 100 VAC~120 VAC, 200 VAC~240 VAC, 50 Hz~60 Hz. |

| input and output | 1 USB 2.0 peripheral device port, 1 standard VGA analog output port, 1 15 pin I/O port (male) with 6 analog outputs, and 3 alarm outputs. |

| environmental condition | |

| operation temperature | –10 °C ~ 50 °C |

| Storage temperature | 0 ° C to 50 ° C (with battery)- 20 ° C to 70 ° C (without battery). |

| IP rating | The design meets the requirements of IP66 standard. |

| battery | |

| Type | Single lithium-ion rechargeable battery or optional AA type alkaline battery (battery box that can hold 8 batteries). |

| Battery power supply time | Standard operation, 10 hours; Operate the rotary scanner for 6 to 8 hours. |

| display | |

| Display Size (Width x Height, Diagonal) |

117.4 mm × 88.7 mm, 146.3 mm |

| display type | Full VGA (640 x 480 pixels) color transparent and reflective LCD (liquid crystal display). |

| Screen mode | Normal or full screen, with 8 color screen settings. |

| Grid and Display Tools | 5 grid options; Cross crosshair (displayed only for single trajectory). |

| Connection and storage performance | |

| PC software | NORTEC PC software, included in the basic NORTEC 600 package. Users can view saved files in the NORTEC PC software and also print reports through the software. |

| Data Storage | It can store up to 500 trajectories with a maximum duration of 120 seconds, and has an onboard preview function that can be selected by the user. |

| interface | |

| language | English, Spanish, French, German, Italian, Japanese, Chinese, Russian, Portuguese, Polish, Dutch, Czech, Hungarian, Swedish, and Norwegian. |

| application | The application selection menu helps users to quickly and conveniently configure. Automatic lift off key. |

| Real time reading | You can choose up to two real-time readings that reflect the characteristics of the measurement signal (which can be selected from 5 amplitude measurements and 1 phase angle measurement reading). |

| Eddy current technology specifications (all NORTEC models) | |

| probe Type | Absolute and differential probes, bridge or reflective configurations. The instrument is not only fully compatible with NORTEC PowerLink probes, but also compatible with products from other major probe and accessory suppliers. |

| Probe connector | The 16 pin LEMO and BNC connectors have built-in automatic balancing function (absolute probe) when using the BNC interface. |

| Frequency range | 10 Hz ~ 12 MHz |

| gain | 0 dB to 100 dB, with increments of 0.1 or 1 dB. |

| rotate | 0 ° to 359.9 °, with increments of 0.1 ° or 1 °. |

| sweep frequency | Each partition is variable between 0.005 s and 10 s. In fine grid mode, there are a total of 13.3 partitions. |

| filter | Low pass: 10 Hz to 2000 Hz, as well as broadband. High pass: Off, or 5 Hz to 1000 Hz, users can choose to continuously display filter types in the shape of "number 6" or "number 8". Continuous balance (low-frequency high pass filter): 0.2 Hz, 0.5 Hz, 1.0 Hz. |

| Probe driver | Low, medium, and high (2 V, 5 V, 8 V). |

| Display clear, afterglow retention | Display clear (0.1 seconds to 60 seconds), afterglow retention (0.1 seconds to 10 seconds) |

| Available alarm types | Three simulated alarms. You can choose from the following options: box shape (rectangular box), polarity (circular), sector shape (pie shaped), sweep frequency (time base), conductivity, and coating thickness. |

| Conductivity (NORTEC 600C, NORTEC 600S, and NORTEC 600D) | |

| frequency | 60 kHz or 480 kHz |

| Digital Conductivity Technical Specification | Digital conductivity display, ranging from 0.9% to 110% IACS, or from 0.5 to 64 MS/m. Accuracy: The error is ± 0.5% IACS within the range of 0.9% to 65% IACS, and ± 1.0% above 62% IACS. Meets or exceeds the requirements of BAC 5651 technical specifications. |

| Thickness of non-conductive coating | The range of measurable non-conductive coating thickness is from 0 mm to 0.648 mm. The accuracy is 0.025 mm (± 0.001 in.) within the range of 0 mm to 0.64 mm. |

| Scanner (NORTEC 600S and NORTEC 600D) | |

| Scanner compatibility | Can be used with Olympus scanners (MiniMite, SpitFire, RA-2000, and PS-5), as well as scanners from other major suppliers, with scanner speeds ranging from 120 RPM to 3000 RPM. |

| Dual band (NORTEC 600D) | |

| Frequency adjustment (dual frequency mode) | Two completely independent frequencies that can operate simultaneously under the same trigger. |

| Blend options | F1 – F2、F1 + F2, And automatic real mixing. |

Standard set of components

The NORTEC 600 has all of the following configurations:

modelBasic, conductivity (C), scanner (S), and dual frequency (D)

power lineCan provide more than 11 types of power cords (for DC adapters)

Keypad and instruction labels: English, international symbols (icons), Chinese or Japanese

Easy Beginner's ManualUp to 9 language versions are available

Items included in all NORTEC 600 models*NORTEC 600 instrument with manufacturer installed wrist strap, "Easy Start Guide", ISO-15548 certificate, hard shipping case, DC adapter with power cord, 67 Wh lithium-ion battery, AA battery box, USB communication cable, MicroSD memory card and adapter, PowerLink probe cable, as well as NORTEC PC software and CD containing product manual.

*The standard kit may vary depending on your location. To learn more about the situation, please contact your local dealer.

Additional items only available for NORTEC 600C model: 19 mm, 60 kHz conductivity probe; Conductivity calibration standard test block (one set of two: 29% and 59%); And calibrate the gasket.

interface

Clear, intuitive, and easy-to-use interface

Integrating high efficiency and simplicity

When developing the user interface for the NORTEC 600 instrument, Olympus aims to create a nearly perfect interface that combines simplicity, efficiency, and intuitiveness. The result of the development is a completely redesigned browsing system. This system greatly reduces the learning curve while maintaining a high level of productivity during the detection process, even inexperienced operators can achieve this.

All the advantages and features of this redesigned user interface can be expressed in as many as 15 languages.

Application selection and all settings

In order to meet the needs of customers, the NORTEC 600 has carefully designed a new application selection menu that includes pre-defined manufacturer settings that can save signal calibration time.

The instrument also comes with a new settings page that displays all parameters on the screen at once, allowing users to quickly configure the instrument to meet the requirements of a specific program.

Signal calibration in freeze mode

The innovative new feature of NORTEC 600 allows operators to focus on the movement of the probe to ensure satisfactory scanning. Then, while the signal is in frozen mode, users can also adjust the gain and phase angle.

Convenient file archiving and report production process

Just press the shortcut key to save files or display reference signals

Just press the newly added save button to immediately save the current settings (program) and signals (data) in the same file in the instrument's memory, greatly enhancing the convenience of operation.

Just press the newly added save button to immediately save the current settings (program) and signals (data) in the same file in the instrument's memory, greatly enhancing the convenience of operation.

The screenshot function can also be delayed, allowing users time to correct their hand position and complete appropriate scanning operations before the instrument actually begins capturing screen images. The onboard memory can store 500 files, which can be transferred to another instrument or a computer as needed.

The user can also call the background reference signal from the memory in a new and faster way: when the real-time signal is displayed on the screen, just press and hold the save key to transmit these same signals to the background.

Intuitive file management

The new file manager menu of NORTEC 600 has been completely rationalized and improved, without losing its operational convenience or reducing its detection efficiency. The file manager has added a file preview feature that allows users to browse through different files in a very intuitive way. Once the appropriate file is found, the user can call it at their convenience.

The file manager menu also allows users to edit, overwrite, and delete any file with minimal steps. The onboard text editor can facilitate users to edit file names, user and instrument information, or simply add annotations at the testing site.

Use NORTEC PC software to easily archive files

During the inspection process, the new PC software NORTEC PC can be used to view the recorded defect indications at any time. The NORTEC PC software enables users to easily exchange files between the NORTEC 600 instrument and their computer. Communication can be established through a USB cable, and all files can be quickly downloaded and uploaded. After the file is transferred to the computer, users can view the file, copy the file to the clipboard, or export the file as a PDF report. NORTEC PC also comes with a new "PDF All" function, which can generate the entire inspection report with just one click, making archiving operations more convenient.

application

Excellent signal performance reflected in practical applications

surface inspection

The high-performance and high-quality electronic devices of NORTEC 600, along with its unique bright display, provide unprecedented high-quality signals for surface inspection applications.

The NORTEC 600 instrument also includes all standard features for mid to high frequency surface detection, including impedance map display, 10 × 10 grid, sweep frequency (strip chart), multiple alarm configurations, automatic lifting, and other functions.

The new features of NORTEC 600, such as balance point crosshairs, fine (extended) grids and mesh grids, and automatic internal balancing circuits (when using BNC interface), make it an extremely proficient tool for surface inspection applications.

Wheel inspection

The application of wheel inspection can best demonstrate the level of perfection of NORTEC 600 advanced electronic circuits. The probe used for this application usually displays low amplitude signals, so a preamplifier is often required. However, due to the wide gain range (0-100 dB) and state-of-the-art electronic equipment of the NORTEC 600, the instrument can transmit high-quality signals during wheel inspection without the need for a preamplifier.

Improved filters (600S and 600D) for bolt hole detection

The NORTEC 600 has a simplified configuration and an improved filter system, making it an ideal instrument for bolt hole (rotary scanner) detection. The newly added NORTEC 600 filter is set by default to display a response signal resembling the number 6 (which is a typical signal shape for rotating bolt hole applications). Users can also set the filter to display a response signal resembling the number 8 according to their own needs. For easier configuration, operators can also activate the new link option, which can automatically adjust the filter settings based on the speed of the scanner.

Conductivity and coating thickness measurement (600C, 600S, and 600D)

The improved conductivity mode of NORTEC 600 has added a simple and clear calibration guide, which includes user-defined conductivity and coating thickness reference information. The NORTEC 600 can measure the conductivity of non ferromagnetic materials and the thickness of non-conductive coatings as thin as 0.64 mm on the material.

Optimization configuration suitable for weld seam inspection

The NORTEC 600 instrument features a compact, portable, and durable model, making it perfect for weld seam testing applications in extremely harsh environments. When the inspection personnel climb to a high place with ropes to inspect the weld seam, they can connect the chest strap to the anchoring devices at the four corners of the instrument and hang the instrument on their chest to inspect the weld seam.

The NORTEC 600 comes with a ready to use weld setup, which simplifies the preparation and calibration process of the instrument. The paint layer thickness can also be evaluated in single frequency or dual frequency mode (only available for NORTEC 600D model).

Traditional stepper scanners support the detection of critical holes (600S and 600D)

The detection of critical holes using NORTEC 600 is simple and the results are reliable. Thanks to NORTEC 600's support for traditional PS5 stepper rotary scanners, improved waterfall display, and newly added layer cursor, NORTEC 600 can easily and accurately locate defects in layered structures.

PS5-AL traditional stepper scanner

Waterfall display with new layer recognition cursor.

Innovative performance of dual frequency detection

Multi in one display (600D)

The newly added all-in-one display can display up to three configurable trajectories for frequency 1 channel, frequency 2 channel, and hybrid channel. Each channel can be displayed as an impedance graph or a strip graph, and each display position can be independently controlled.

Automatic mixing (600D)

The newly added automatic mixing function of NORTEC 600 can immediately mix signals together, thereby minimizing the remaining (subtracted) signals. This function is particularly suitable for the inspection of heat exchanger fittings.

Real time reading

With the help of real-time reading parameters, users can select up to two real-time display values from several signal measurements on the screen in standard or full screen mode of the instrument. The various measurement values displayed on the screen indicate the various wave amplitudes of the signal at different phase angles.

- Select 3 types of peak to peak amplitude measurements (horizontal, vertical, or magnitude)

- The maximum horizontal or vertical distance calculated from the equilibrium point

- Angle (phase) measurement value of peak to peak signal