1、 Product usage scope:

Fully automatic honey pill making machineWidely used, it is an ideal pill making machine for pharmaceutical laboratories, pharmaceutical factories, health food factories, hospital preparation rooms, clinics, pharmacies, and other facilities.

2、 Dismantling and installation of cutting tools and accessories

1. After tightening the dedicated retraction nut with the pill making knife, tighten the top thread of the retraction nut to retract the pill making knife.

2. Spring loading and unloading methods and installation direction:

Remove the pellet making knife, use a wrench to hold the knife shaft, and look at the connection thread on the right side of the knife shaft from the front, which is right-handed, while the left side is left-handed. After removing the bolts on the flange seat of the blade shaft, unscrew the blade shaft, and then hold the blade shaft and pull it forward. The flange seat, gear body blade shaft, and spring can be pulled out at once. Removing the flange seat and gear body direction can replace the spring (left side is a left-hand spring, right side is a right-hand spring).

3. Guide key disassembly method and installation direction:

After removing the flange seat, press the spring to move the gear body forward by 10mm and remove the guide key. Do not exit together with the gear body to avoid the guide key getting stuck in the retreat groove of the blade shaft.

3、 Common causes and solutions of malfunctions:

fault |

cause |

processing method |

The pill shape is not round |

The pill making knife is not aligned correctly Uneven thickness of medicine strips |

Zhengzheng Maru Knife Replace the strip outlet |

Inaccurate dosage |

Uneven thickness of medicine strips |

Replace the strip outlet |

Sticky knife |

Low alcohol content or inability to spray The pill making knife has local burrs |

Add alcohol quantity Remove the burrs |

Alcohol cannot be sprayed out |

No alcohol or pipeline blockage |

Add alcohol to remove blockages |

4、 Product Introduction:

The fully automatic pill making machine is a new type of pill making machinery launched by our company. It is a specialized pill making equipment for the pharmaceutical industry. Bringing together the advantages of various fully automatic pill making machines into one machine, it has the advantages of round pill shape, accurate dosage, fast disintegration, smooth dispensing, no shed material, smooth transmission, easy operation, and extremely low failure rate. And the contact area between the machine and the drug, as well as the overall enclosure, are made of stainless steel material. The casing is bright, easy to clean, and meets GMP standards and specifications. (Note: We can customize tool specifications according to customer needs and make pills that satisfy customers.)

5、 Structural features:

1. This machine consists of two parts: strip making and pill making, with a box structure and horizontal strip making. It has a simple structure, easy operation, and convenient maintenance.

2. The strip adopts a worm gear reducer for smooth and reliable transmission.

3. The rolling and cutting mechanisms of the pill making part are located in the same gearbox, with good lubrication conditions for the components, and the cutting speed can be achieved without any issues

4. The knob adjustment of the variable speed gearbox allows the rolling cutter to achieve a speed of 6-30 revolutions per minute until the cutting speed matches the strip speed.

5. The feeding port is large, and the pressure plate flips to press the material, which is convenient for filling and can eliminate the phenomenon of shed material. The hopper is divided into upper and lower parts by the flipping axis, which is very convenient to open during cleaning.

6. Electric heating uses electric heating tubes, which are safe, reliable, and have smooth strips.

7. Drip the medicine strip with alcohol, and the outside of the pill making knife is equipped with a brush to prevent sticking of the knife. The alcohol is stored in the square box of the dispensing mechanism, and the amount of alcohol is adjusted through a ball valve.

6、 Technical parameters:

Scope of application: Φ 16mm pills (3g) to Φ 24mm pills (9g)

Production: 50kg/hour based on 6 grams of 20mm pills

Volume: 1250mm×650mm×980mm

Output motor power: Y100L-6 1.5KW 940 RPM 380V

Pill making speed regulating motor power: YCT112-4A 550W

Pill making speed range: 125-1250 revolutions per minute

Weight: 600kg

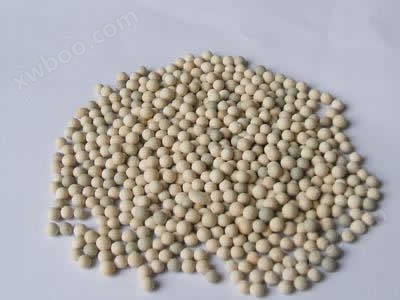

7、 Finished product display

8、 Precautions for use:

1. This machine is suitable for ambient temperatures ranging from -5 ℃ to+40 ℃, relative humidity less than 90%, and fluctuations in grid voltage amplitude

2. Before driving, it is necessary to check whether the oil level of the gearbox has reached the standard position; Check if the oil cup on the hopper is filled with cooking oil; Check if the pill making machine is aligned and tightened; Check if the liquor cleaning system is unobstructed and adjust the appropriate amount. Disinfect the guide wheel, guide frame, pellet making knife, etc. with alcohol. Turn on the electric heating.

3. The delivery part will be air freighted for 3-5 minutes, and if there are no abnormalities, the material can be fed. Break the discharge strip, return a portion of it to the hopper, and wait for the strip to pass before opening the pellet making section. The feeding should be uniform during operation. If it is found that the dispensing and pill making are not synchronized, they can be adjusted by turning the knob. Clockwise pill making is faster, while counterclockwise pill making is slower. The size of the pill diameter can be achieved by replacing different dispensing ports, pill making knives, and guide wheels.

4. When feeding, foreign objects should not be thrown into the hopper, and hands should not be inserted into the flat surface of the hopper to avoid being crushed by the pressure plate. Regularly check for any abnormalities in various components, and immediately stop and inspect if any abnormalities are found.

5. After use, power off and turn off the main switch and other switches. Remove the strip outlet and electric heating cover before cleaning. When disassembling the machine head, a hook wrench (special) can be used, and then the bracket and propeller can be pulled out. Open the upper part of the hopper and clean the two flip plate shafts. After cleaning, apply cooking oil. When reusing, use alcohol to remove oil and disinfect each part.

6. The oil inside the reducer should be kept at the no oil mark. After two to five months of normal operation, the waste oil should be drained and replaced with new oil. Add cooking oil to the oil cup on the hopper three times per shift, and add an appropriate amount of engine oil to other gear sprocket points.

Video viewing:

Related product keywords:Price of fully automatic honey pill making machineFully automatic honey pill making machineFully automatic honey pill making machine for sale